Manufactur standard Plastic Injection Mold Parts - Dispenser Tray – Uni-Moulding

Manufactur standard Plastic Injection Mold Parts - Dispenser Tray – Uni-Moulding Detail:

Ground Box Mould

Export Country:

America

Completion Time:

1 Month

Tag: Dispenser Tray

Challange

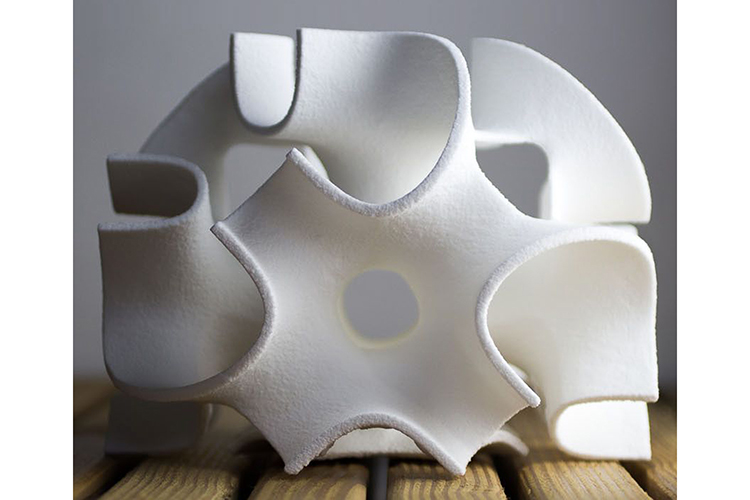

As the part is to be transparent with colors and many processes for final product. Assembly for the feet,silk printing. The most important thing is to control the transparency without black dots.

Solutions

Have it run in our clean injection molding shop. That’s our advantage.

Product Application Field

Mainly for pets to put food and drinks.

Story

The product is in direct contact with pets. The customer requires that the materials need to be NSF certified, and the appearance is beautiful and translucent. Finally, we chose MS materials.

Main Challenges

Plastic injection moulding: MS material properties are relatively unstable. In addition to the product structure and customer requirements for product appearance, we adjust and increase the cooling system temperature to control the product appearance, and use hot runner technology to improve the beauty of gate position.

Silk screen printing advantage:

(1) It is not limited by the size and shape of the substrate

Generally, printing can only be carried out on the plane, and screen printing can not only print on the plane, but also print on shaped objects with special shapes, such as spherical surfaces. Anything with shapes can be carried out by screen printing.

(2) The layout is soft and the printing pressure is small

The screen is soft and elastic.

(3) Strong ink layer coverage

It can be printed in pure white on all black paper with strong three-dimensional feeling.

(4) Suitable for various types of inks

(5) Strong optical rotation resistance

It can keep the luster of printed matter unchanged. (temperature and sunlight have no effect). This makes it possible to print some self-adhesive without additional lamination and other processes.

(6) Printing methods are flexible and diverse

(7) Plate making is convenient, the price is cheap and the technology is easy to master

(8) Strong adhesion

(9) It can be pure manual silk screen printing or machine printing

(10) Suitable for long-term display and expressive advertising outdoors

Main Technology

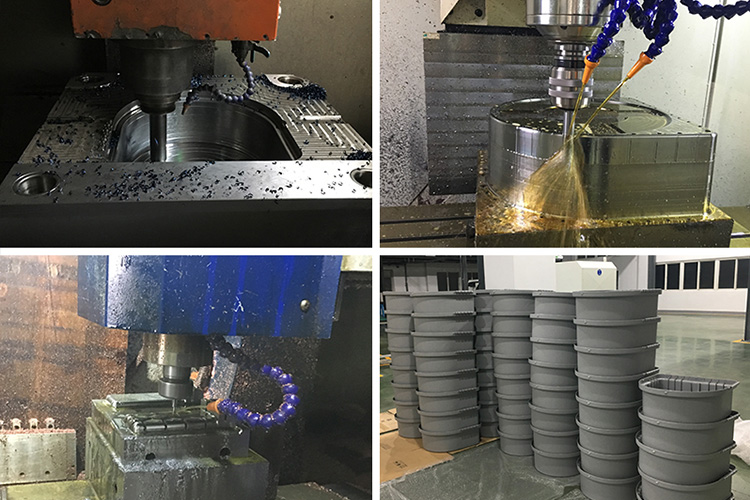

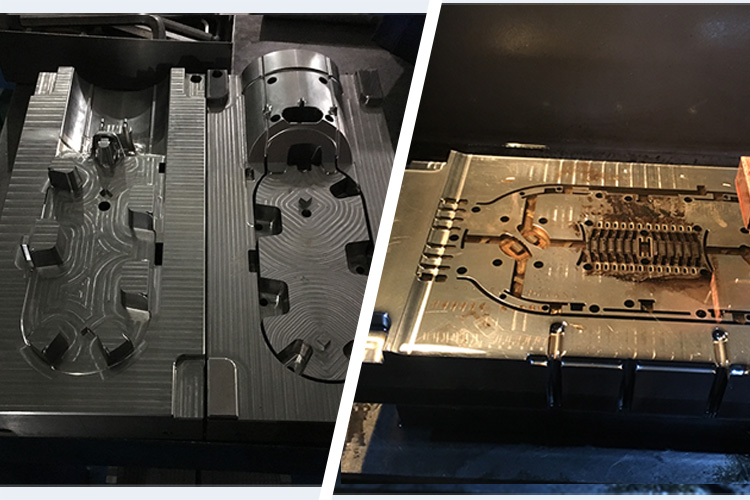

Mold Analysis, CNC Rough Machining, Heat Treating, Finishing Machining, Wire Cutting, EDM, Polishing, Texture.

Mold Details:

Maximum die size: 400*400*300mm

Export Area: USA

Delivery time: 30 days

Part Quantity: 1 pcs

Mold Quantity: 1 sets

Number of Processed Sliders: 0 pcs

Mold Material: 718H, NAK80, P20, 718, 45#, etc.

Part Material: MS

Project Leader: Zach Zhao

Product detail pictures:

Related Product Guide:

Our pursuit and company intention is usually to "Always fulfill our purchaser requirements". We go on to acquire and layout excellent high quality products for both our previous and new consumers and realize a win-win prospect for our customers too as us for Manufactur standard Plastic Injection Mold Parts - Dispenser Tray – Uni-Moulding , The product will supply to all over the world, such as: California , Bahamas , Georgia , We are sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy you with our high-quality products and perfect service . We also warmly welcome customers to visit our company and purchase our products.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.