-

Massive Selection for Injection Molding Usa - Cable slack tray – Uni-Moulding

Ground Box Mould Export Country: India Completion Time: 1 Month Tag: Injection Mould Challange There are many angle lifters applied for the mould and space for some of the lifters were very tight. But the customer has to get the features as required. Solutions Have the mechanism changed for these features. Product Application Field Industrial communication cable tray Main Challenges The position of the winding reel in the middle of the product has a thin wall th... -

China wholesale Co-Extrusion Tooling - Cable slack tray – Uni-Moulding

Ground Box Mould Export Country: India Completion Time: 1 Month Tag: Injection Mould Challange There are many angle lifters applied for the mould and space for some of the lifters were very tight. But the customer has to get the features as required. Solutions Have the mechanism changed for these features. Product Application Field Industrial communication cable tray Main Challenges The position of the winding reel in the middle of the product has a thin wall th... -

High Performance Iml Injection Molding - Professional Bottle Cap Mold – Uni-Moulding

Professional Bottle Cap Mold Mold core and cavity are made of S136 steel after heat treatment to ensure hardness and life. Hot runner system with German heating elements accelerates plastic flow in the molten state, saves materials, and ensures product quality stability. Use advanced processing equipment to process molds with high precision. In addition, bridge-type three-coordinate measuring instruments and articulated arm measuring instruments are used to precisely control mold s... -

Factory Supply Molds For Plastic - 3D Print – Uni-Moulding

3D Print Material limitations Although high-end industrial printing can print plastics, some metals or ceramics, the materials that cannot print are relatively expensive and scarce. In addition, the printer has not reached a mature level and can not support all kinds of materials in daily life. Researchers have made some progress in multi-material printing, but unless these advances are mature and effective, materials will still be a major obstacle to 3D printing. Machine li... -

High Quality for Silicone Injection Molding - 3D Print – Uni-Moulding

3D Print Material limitations Although high-end industrial printing can print plastics, some metals or ceramics, the materials that cannot print are relatively expensive and scarce. In addition, the printer has not reached a mature level and can not support all kinds of materials in daily life. Researchers have made some progress in multi-material printing, but unless these advances are mature and effective, materials will still be a major obstacle to 3D printing. Machine li... -

China Manufacturer for Automotive Injection Molding - Office Chair Back – Uni-Moulding

Office Chair Back Export Country: England Completion Time: 1 Month Tag: Office Chair Back Challange The part line is curved, not straight and not ejection pins applied . Solutions It highly depends on the mold maker’s skill and knowledge. We are lucky to have our own mold makers who fulfills the job over 20 years. Product Application Field Office chair,Office Supplies Main Challenges PVC corrosion mold: S136 heat treatment is adopted to increase the hardn... -

Best-Selling Professional Injection Mould - ABS extruded profile – Uni-Moulding

ABS extruded profile Our extruded Mold core are made of Assarb S136 steel after heat treatment to ensure hardness and life. In addition to ABS extrusion applications, also we have rich experience in PP, TPE, PVC etc. material manufacturers. Our extruded products are widely used in automobile, architecture, decoration and other fields. Discover the difference an engineering driven supplier can make for your company. Regardless of your needs, UNI has the capabilities to partner with y... -

-

factory customized Medical Injection Molds - ABS extruded profile – Uni-Moulding

ABS extruded profile Our extruded Mold core are made of Assarb S136 steel after heat treatment to ensure hardness and life. In addition to ABS extrusion applications, also we have rich experience in PP, TPE, PVC etc. material manufacturers. Our extruded products are widely used in automobile, architecture, decoration and other fields. Discover the difference an engineering driven supplier can make for your company. Regardless of your needs, UNI has the capabilities to partner with y... -

Personlized Products Injection Molds Service - Professional Bottle Cap Mold – Uni-Moulding

Professional Bottle Cap Mold Mold core and cavity are made of S136 steel after heat treatment to ensure hardness and life. Hot runner system with German heating elements accelerates plastic flow in the molten state, saves materials, and ensures product quality stability. Use advanced processing equipment to process molds with high precision. In addition, bridge-type three-coordinate measuring instruments and articulated arm measuring instruments are used to precisely control mold s... -

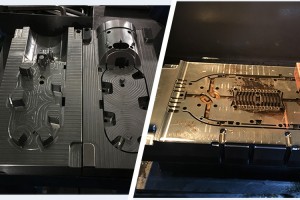

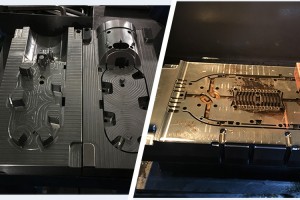

Manufactur standard Plastic Injection Mold Parts - Pole Slack Box – Uni-Moulding

Pole Slack Box Export Country: South Africa Completion Time: 1 Month Tag: Plastic Injection Mold Challange Time schedule: The customer needed it to be finished within 30 days which is not a small mold and with many processes. Especially for so many ribs to be EDM work. Solutions Several Machines are working for this tool to finish the job as fast as possible. We made it in time. Product Application Field Outdoor power equipment protection box. It mainly prevents the... -