Competitive Price for Injection Moulding Step By Step - ABS extruded profile – Uni-Moulding

Competitive Price for Injection Moulding Step By Step - ABS extruded profile – Uni-Moulding Detail:

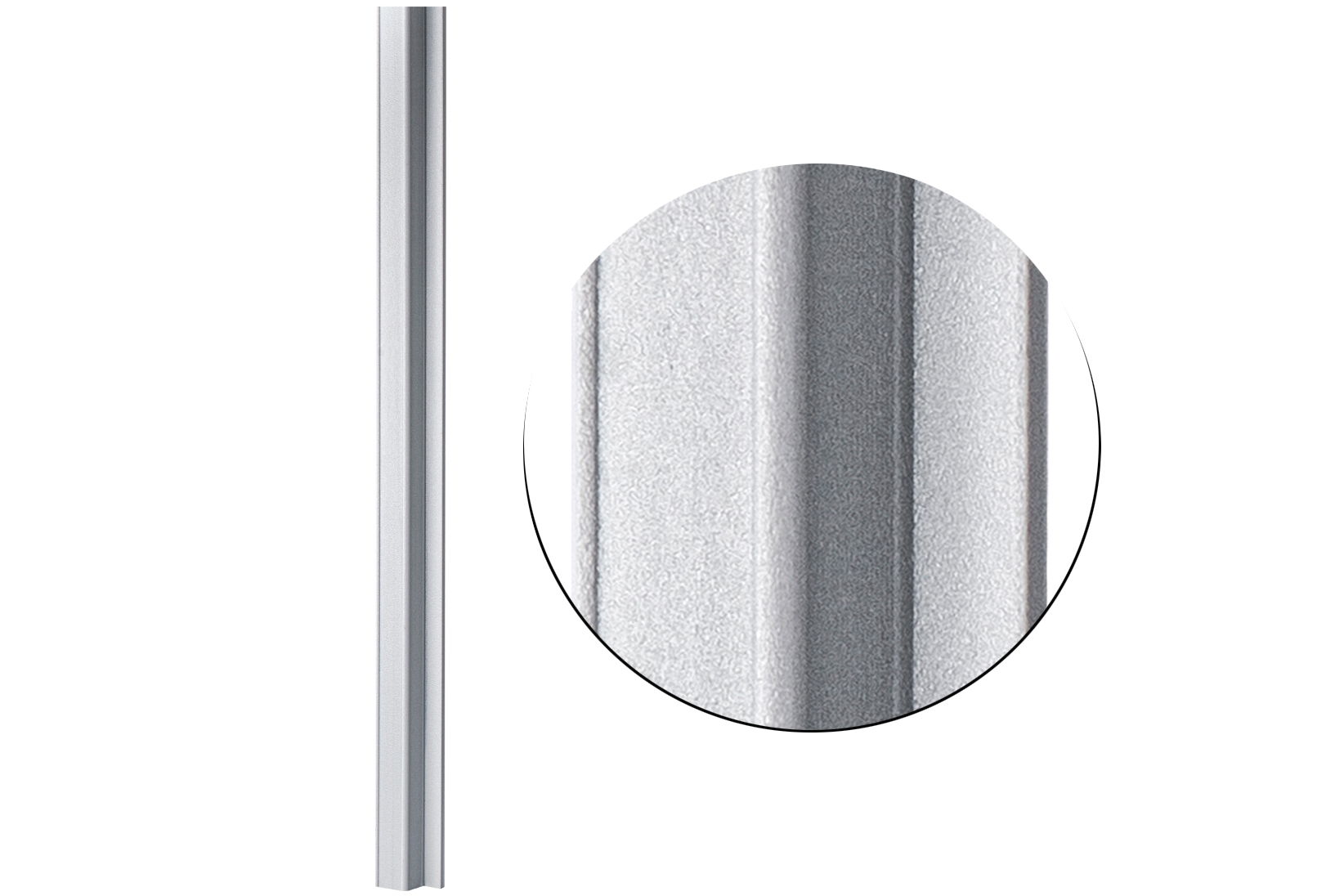

ABS extruded profile

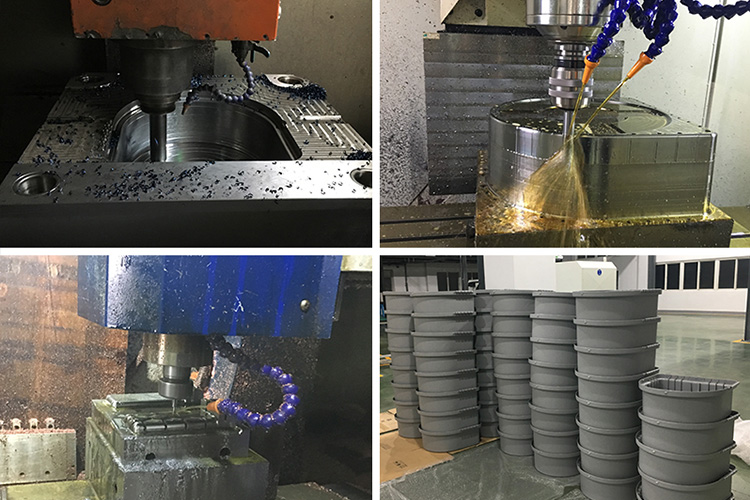

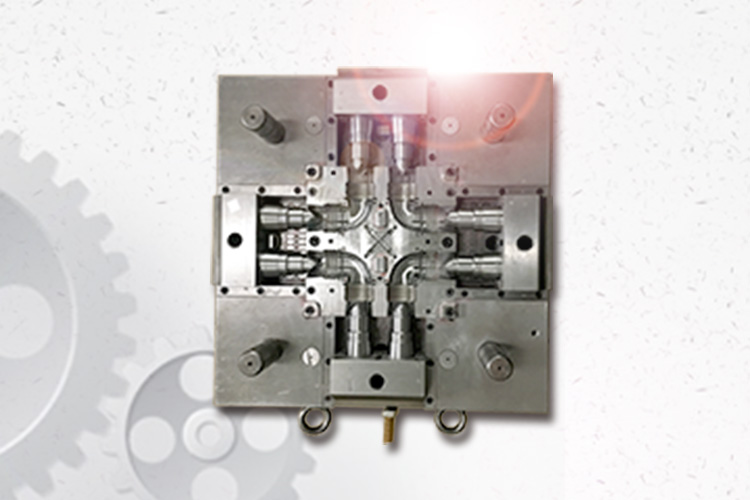

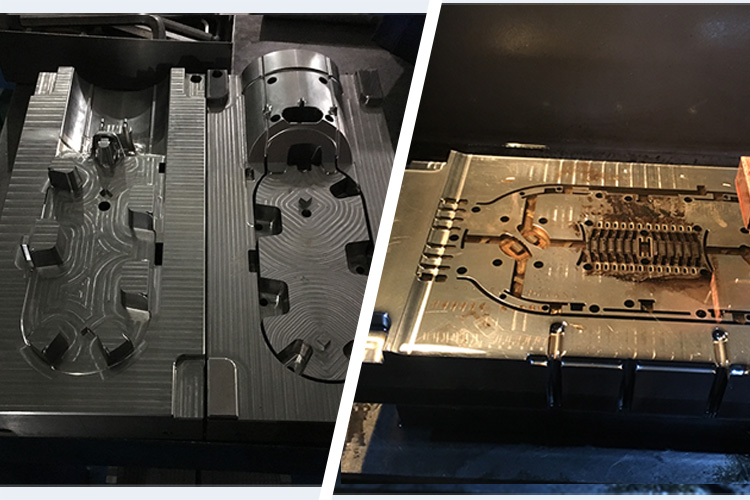

Our extruded Mold core are made of Assarb S136 steel after heat treatment to ensure hardness and life.

In addition to ABS extrusion applications, also we have rich experience in PP, TPE, PVC etc. material manufacturers.

Our extruded products are widely used in automobile, architecture, decoration and other fields.

Discover the difference an engineering driven supplier can make for your company. Regardless of your needs, UNI has the capabilities to partner with you on a level you never thought possible. One phone call, one solution…

Very few manufacturers are able to keep everything “in-house” these days, in fact, it usually is not in their own best interest to do so. But for molds are very specialized mechanic field, it is very hard for an unprofessional person to find a very strong background for molds. When you come to a budget is lower than what we do in-house, we can have the solutions sourced overseas as Vietnam with the quality controlled by our professional engineering team from the tooling design to production. Each stage is well organized and evaluated with our technology to meet with your requirements.

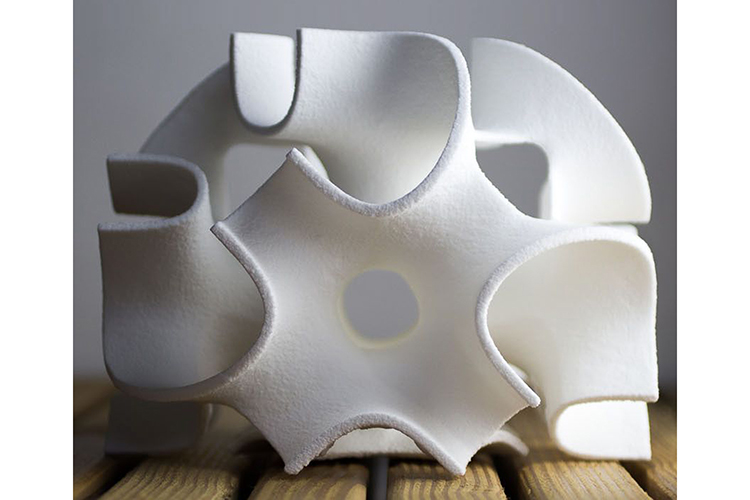

Collaborating with our customers’ engineers is where it all begins. For 10 years, Uni-Moulding has been helping our clients bring their concepts to reality. Our design engineers are involved from day one, working through the unique manufacturing issues of bringing each product to market: material selection, process specifications, complex tooling mechanics, aesthetics, reverse engineering, whatever the challenge may be. We apply creative and functional strategies to help you achieve your goals in a timely and cost-effective manner.

Our design engineers are ready to help you develop your application and adapt it to handle the demands of real world environments.

Product detail pictures:

Related Product Guide:

Persisting in "High quality, Prompt Delivery, Competitive Price", we have established long-term cooperation with clients from both overseas and domestically and get new and old clients' high comments for Competitive Price for Injection Moulding Step By Step - ABS extruded profile – Uni-Moulding , The product will supply to all over the world, such as: Wellington , venezuela , Ethiopia , We look forward to hearing from you, whether you are a returning customer or a new one. We hope you will find what you are looking for here, if not, please contact us immediately. We pride ourselves on top notch customer service and response. Thank you for your business and support!

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.