Cheapest Factory Medical Plastic Injection Mold - 3D Print – Uni-Moulding

Cheapest Factory Medical Plastic Injection Mold - 3D Print – Uni-Moulding Detail:

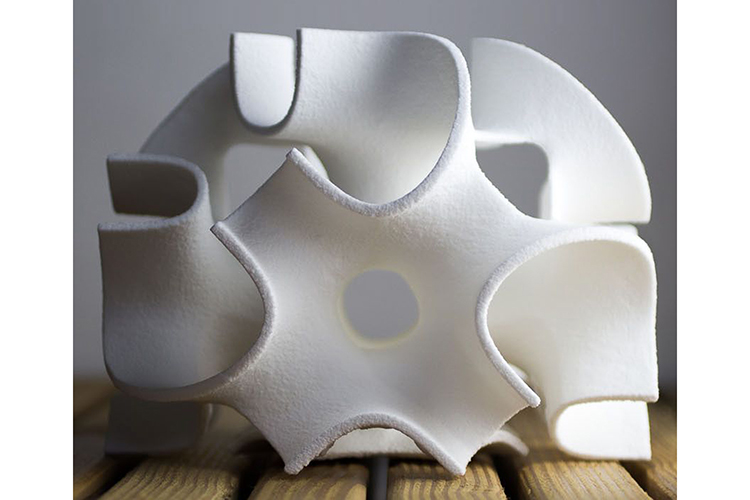

3D Print

Material limitations

Although high-end industrial printing can print plastics, some metals or ceramics, the materials that cannot print are relatively expensive and scarce. In addition, the printer has not reached a mature level and can not support all kinds of materials in daily life.

Researchers have made some progress in multi-material printing, but unless these advances are mature and effective, materials will still be a major obstacle to 3D printing.

Machine limitations

3D printing technology has achieved a certain level in reconstructing the geometry and function of objects. Almost any static shape can be printed, but those moving objects and their clarity are difficult to achieve. This difficulty may be solvable for manufacturers, but if 3D printing technology wants to enter ordinary families and everyone can print what they want at will, the limitations of the machine must be solved.

Intellectual property concerns

In the past few decades, more and more attention has been paid to intellectual property rights in the music, film and television industries. 3D printing technology will also be involved in this problem, because many things in reality will be more widely spread. People can copy anything at will, and there is no limit to the number. How to formulate 3D printing laws and regulations to protect intellectual property rights is also one of the problems we face, otherwise there will be flooding.

Moral challenge

Morality is the bottom line. What kind of things will violate the moral law is difficult to define. If someone prints out biological organs and living tissues, they will encounter great moral challenges in the near future.

Commitment of expenses

The cost of 3D printing technology is high. The first 3D printer sold for 15000. If you want to popularize to the public, price reduction is necessary, but it will conflict with the cost.

At the beginning of the birth of each new technology, we will face these similar obstacles, but we believe that finding a reasonable solution, the development of 3D printing technology will be more rapid, just like any rendering software, which can be continuously updated to achieve the final improvement

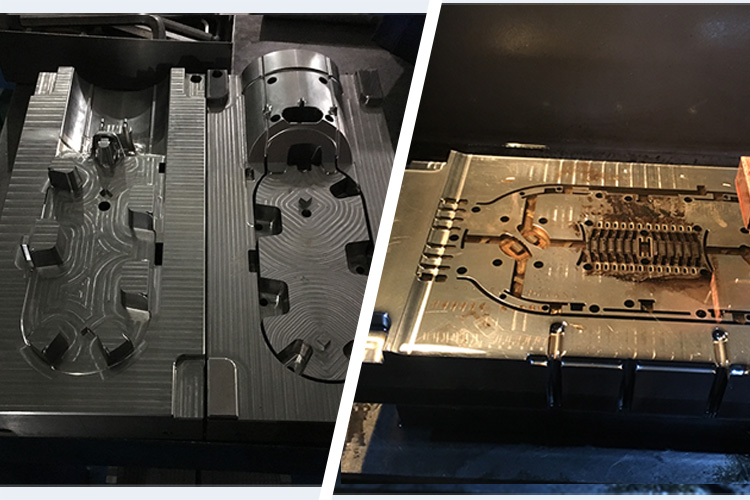

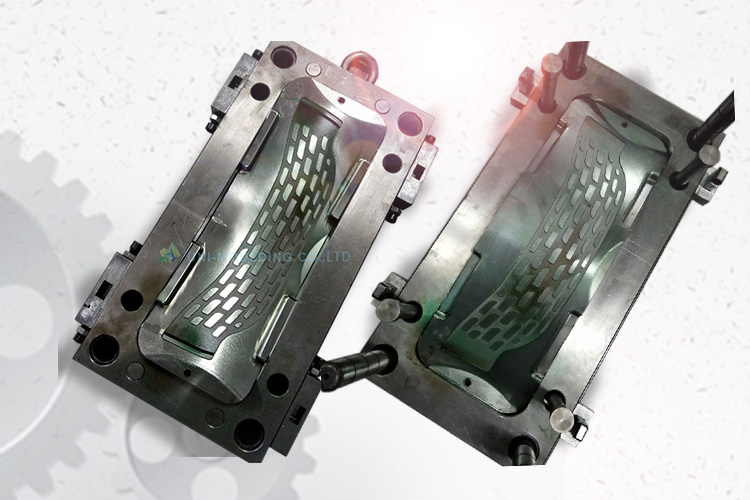

Product detail pictures:

Related Product Guide:

We insist about the theory of growth of 'High excellent, Performance, Sincerity and Down-to-earth working approach' to offer you with great company of processing for Cheapest Factory Medical Plastic Injection Mold - 3D Print – Uni-Moulding , The product will supply to all over the world, such as: Manila , Lyon , Slovenia , Taking the core concept of "to be the Responsible". We will redound up on society for high quality products and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.